-

Mr. LuoHigh quality product, fast responding for my every inquiry, thanks for your biggest support!,

Mr. LuoHigh quality product, fast responding for my every inquiry, thanks for your biggest support!, -

Mr. BowleyEvery time send you email, we can always get reply at the first time,you provide us the best service, thank you!

Mr. BowleyEvery time send you email, we can always get reply at the first time,you provide us the best service, thank you! -

Mr. ZhangYour products have high cost-performance, it is even better than some of the US manufacturer, it is my correct choice to choose you as partner!

Mr. ZhangYour products have high cost-performance, it is even better than some of the US manufacturer, it is my correct choice to choose you as partner! -

Mr. RichardYour HD pole camera is very fashion and with high reliable quality, the customers like it very much. I believe our cooperation will better and better in the future.

Mr. RichardYour HD pole camera is very fashion and with high reliable quality, the customers like it very much. I believe our cooperation will better and better in the future.

High Intensity LED UV Curing System CIPP Curing No Dig Rehabilitation For Pipe Diameter From 150-1600mm

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| For Pipe Diameter | 150-1600mm | Model | HT-1600 |

|---|---|---|---|

| Type | LED | Control Interface | Touch Screen |

| Cable Drum | Automatic | Warranty | 1 Year |

| Highlight | CIPP LED UV curing system,High intensity LED UV curing system,1600mm LED UV curing system |

||

UV-CIPP curing system takes high reliable SPS control system to control all the operations. Human-computer interaction takes high light Siemens MIMIC touch screen, and remote control, diagnosis functions can be expanded. The electrical cable drum is equipped with standard 200m high temperature resistance UV curing cable, can be extended to 300m. The electrical light source can satisfy DN150-2000mm pipe no-dig rehabilitation. The whole system has a compact design, and suitable for installation on all kinds of trucks.

| Items | Description | Qty | Specifications |

| 1 |

Small light source

|

2 pcs |

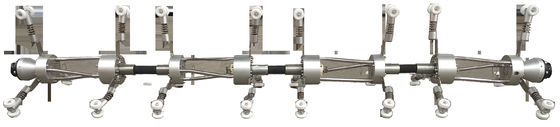

1. For pipe diameter: DN150-800. 2. Light chain consisting of 2 units each with 4 UV high power lamps, total 8 lamps, power levels: 400/500/650W,total power 5200W. 3. 1 sensor for air temperature measurement; 4 sensors for at the inner liner surface(IR-sensor); 4. Each light chain can replace and install in random, no requirement of installation sequence. 5. The front plug-in heat-resistant camera, equipped with high power LED light. 6. Installation and adjustment of light chain wheels and legs is easy and convenient, to meet the requirement of quick replacement for different pipe diameters and different shapes of pipes in field. 7. Pre-set the ignition intervals of UV lamp, the system will control lamp ignition and flame-out automatically according to the pre-set time. You can also choose manual control to handle the complicated field situation.

|

| 2 |

Large light sources

|

2 pcs |

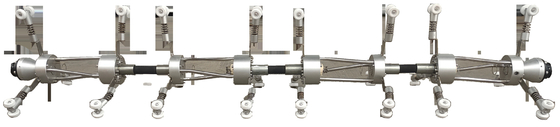

1. For pipe diameter: DN600-1600. 2. Light chain consisting of 2 units each with 4 UV high power lamps, total 8 lamps, power levels:1000/1200/1500W, total power 12000W. 3. 1 sensor for air temperature measurement; 3 sensors for at the inner liner surface(IR-sensor); 4. The light chain wheel set and legs are driven by motor, can stretch out and draw back in pipes automatically, to finish operation in large pipes quickly. 5. The front plug-in heat-resistant camera, equipped with high power LED light. 6. Installation and adjustment of light chain wheels and legs is easy and convenient, to meet the requirement of quick replacement for different pipe diameters and different shapes of pipes in field.

|

| 3 |

Cable reel

|

1 pcs |

1.Cable: standard length 150m, heat resistant, UV resistant, for control of curing, video signal transmission, light source driving. 2.Cable reel: transparent design for outer rack, reduce weight, convenient for repair, with inner lighting system. 3.Back eye camera: for inspection of liner material. |

| 4 |

Control unit

|

1 pcs |

1.PLC controlled switch gear for operating the cable drum and UV light chain. Operation by the innovative Siemens touch screen. 2.Windows operation system. All curing information and videos are visible. Display and record the following data: speed, pressure, liner surface temperature, light chain status and length, data can be exported. 3.Computer with software and 3 monitors, including: 1 x 15” TFT monitor for operation and control of the entire system; 1 x 17” TFT monitor for image transmission of camera; 1 x 22” TFT monitor for software and operation of the entire system. |

| 5 | Blower and control unit | 1 pcs |

1.High power blower, power: 1400m3/h,nominal power: 18.5kW,50Hz, max. pressure 0.7bar. 2.Deep-developed control system, control the blower by touch screen of control cabin. 3.Plug-in switch connecting with cable drum. 4.Software: Windows system, pressure visualization and calibration, control the liner expansion,. 5.Built-in filter and relief valve, oil free, air cooling.

|

| 6 |

Ties

|

1 set | For pipe diameters:DN150-300,DN300-500,DN500-650,DN800-1000,DN1200-1600 |

| 7 | Generator | 1 set |

40KW, voltage 400V,frequency: 50Hz

|

| 8 | Standard container | 1 set |

Transportation and deployment

|